Edible oil is vital to our diet, but it often contains impurities such as coloring and waxes that affect the quality of cooking oil.

Activated carbon is essential for decolourizing edible oil, and by removing these impurities, it ensures that edible oil meets international standards.

In this article, we will explore why activated carbon is indispensable in the decoloration of edible oils.

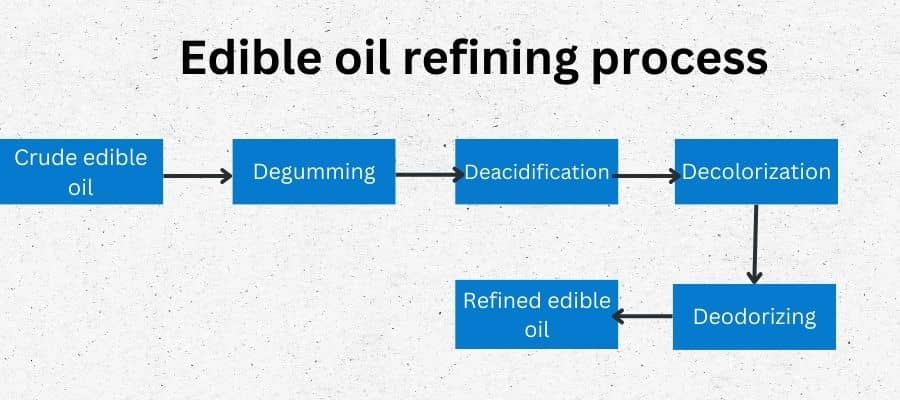

Edible oil decolorization process

The decolorization process of edible oil refining technology usually adopts adsorption decolorization method. Using activated carbon or activated white clay, the color pigment, trace metal ions, residual saponin, some odor substances and toxic chemicals are removed through the edible oil decoloration process to improve the color and quality of edible oil.

Application of activated carbon in edible oil purification

In the production of edible oil, activated carbon is crucial for the bleaching step, effectively removing pigments, phospholipids, and heavy metals. Its unique adsorption properties also help eliminate oxidation products and trace metals, enhancing the safety and quality of the oil.

Mechanism of activated carbon decolorization in edible oil processing.

Activated carbon utilizes its honeycomb microporous structure and huge specific surface area to effectively adsorb pigments and impurities in crude oil through physical adsorption to enhance oil quality. Specifically, activated carbon decolorization can achieve the following effects.

- Remove Pigments: Activated carbon selectively adsorbs and removes natural pigments like chlorophyll and carotene, brightening the color of vegetable oil.

- Adsorption of Impurities: Activated carbon effectively adsorbs non-oil components such as phospholipids, waxes, and metal ions, slowing oil rancidity and enhancing purity and stability.

- Remove Odor: Activated carbon treatment significantly reduces odors from volatile organic compounds like aldehydes and ketones, making the oil flavor purer and more pleasant.

- Reduce Loss: Compared to traditional alkali refining and white earth decolorization, the activated carbon adsorption method gently decolorizes, retains maximum nutrients in the oil, and minimizes processing loss.

Through the above adsorption principle, activated carbon can effectively remove pigments, oxides, metal ions and other harmful substances from edible oil. This not only improves the color and transparency of the oil, but also enhances the safety and stability of the edible oil.

Decolorizing Carbon for Edible Oil

When selecting activated carbon for decolorizing edible oils, it is equally important to consider the type and characteristics of the activated carbon to ensure decolorization and oil quality. The main type of activated carbon used in this application is wood powdered activated carbon.

Wood powdered activated carbon excels in decolorizing edible oil due to its strong adsorption capacity and microporous structure, enhanced by high-temperature activation. It effectively removes pigments and impurities with minimal dosage, improving decolorization efficiency. Additionally, its good dispersibility facilitates mixing, reducing phospholipids, acid, and peroxide values in oil, thus enhancing quality stability.

The activated carbon products provided by Qizhong are specially designed for decolorization of edible oil with the following characteristics:

- High decolorizing ability at low dosage

- Good dispersion

- Wide applicability

| Description | Wood Powder Activated Carbon |

| Mesh Size | 200/325 mesh |

| Molasses Number | 150-180 |

| Ash≤(%) | 5 |

| Iodine (mg/g) Minimum | 300-1050 |

| Caramel Decoloration (mg/g) | 100-130 |

Conclusion

Through an in-depth understanding of the application of activated carbon in the decolorization process of edible oil, we can see the importance of activated carbon in improving the quality of edible oil.

Choosing the right activated carbon products can significantly improve the safety and market competitiveness of edible oil. As a professional supplier of activated carbon, Qizhong provides many types of activated carbon products that can meet different industrial needs.

If you have any questions about how to choose activated carbon or other related issues, please contact us.