With the global energy transition, lithium-ion batteries play a crucial role in electric vehicles and renewable energy storage. However, the entire lifecycle, from raw material mining to battery production, use, and recycling, faces complex environmental issues.

Activated carbon serves as an efficient and multifunctional adsorbent material, playing a key role in various stages of the lithium battery industry chain. From pollution control in nickel ore mining to degreasing and impurity removal in production, and heavy metal adsorption in the recycling of waste batteries, activated carbon is an indispensable environmental assistant.

This article will explore the multiple applications of activated carbon in the lithium battery industry, especially the importance of degreasing and impurity removal, and how to choose the appropriate activated carbon products.

Why Degreasing and Impurity Removal

The lithium battery industry causes environmental pollution from material mining to waste disposal:

Raw material mining

For example, in the nickel ore mining process, harmful sulfur dioxide and heavy metal-containing dust are released, causing air and water pollution, endangering human health and the ecological environment.

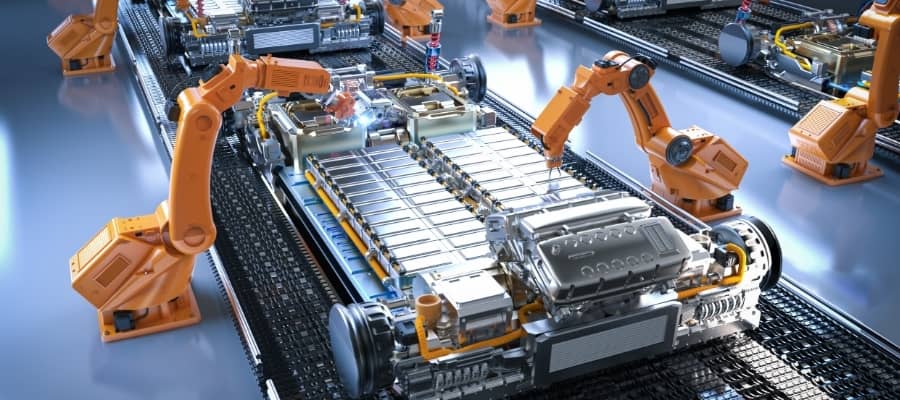

Battery production

The presence of oil and impurities in the preparation of electrode materials and the purification of electrolyte can reduce battery performance, affecting charging and discharging efficiency and battery life.

Waste disposal

Lithium-ion batteries contain heavy metals such as lead, mercury, and cadmium. Improper handling may lead to these toxic substances seeping into the soil and water sources, causing long-term harm to the ecosystem.

Therefore, effective degreasing and impurity removal are not only related to the performance and safety of lithium batteries but also a key link in the environmental protection of the entire industry chain. Activated carbon, as an efficient and economical adsorbent material, can play an important role in multiple stages, helping to solve these problems.

The Application of Activated Carbon in the Lithium Battery Industry

Pollution control

Activated carbon reduces harmful gas emissions and dust in the nickel ore mining process through adsorption, and removes heavy metal ions and other organic pollutants in wastewater treatment, reducing harm to the environment and human health.

Nickel ore liquid purification

In the purification process of laterite nickel ore leachate, activated carbon shows efficient degreasing and impurity removal capabilities, ensuring the smooth progress of subsequent processes.

Purification in battery production

Activated carbon uses its high specific surface area for physical and chemical adsorption to remove oil and impurities in battery production. Its chemical stability ensures the optimization of battery performance while avoiding the introduction of new impurities.

Waste battery recycling

Activated carbon adsorbs heavy metal ions in the recycling process of waste batteries, preventing further environmental pollution by toxic substances

The regenerative capacity of activated carbon further reduces costs in the lithium battery industry and enhances its sustainability throughout the entire battery lifecycle.

Activated Carbon Selection

In the degreasing and impurity removal process of the lithium battery industry, coconut shell activated carbon has become the preferred material due to its unique characteristics. Here are the main advantages of coconut shell activated carbon:

- High oil absorption capacity: It can quickly and effectively remove oil stains in nickel ore liquid and battery production processes.

- Large specific surface area: It is conducive to the efficient removal of various impurities.

- Excellent mechanical strength: Suitable for long-term use.

- Good regenerative properties: The adsorption capacity can be restored through appropriate treatment methods, reducing usage costs.

Our company offers coconut shell activated carbon specifically for degreasing and impurity removal in lithium battery production. This product is made from high-quality coconut shells from Southeast Asia, processed through high-temperature carbonization, activation, crushing, and screening processes.

The product, prepared with high-quality raw materials and advanced production equipment and processes, features high purity, high oil removal, and low dust content.

Contact Us

By choosing our coconut shell activated carbon, you will not only achieve excellent degreasing and impurity removal effects but also enjoy professional technical support and quality after-sales service.

We are committed to providing the best solutions for the lithium battery industry, helping you improve production efficiency, product quality, and effectively reduce environmental impact.