Raw Materials

Depending on your specific application needs, we offer a wide range of materials for cellular activated carbon, including wood, coal and coconut shells.

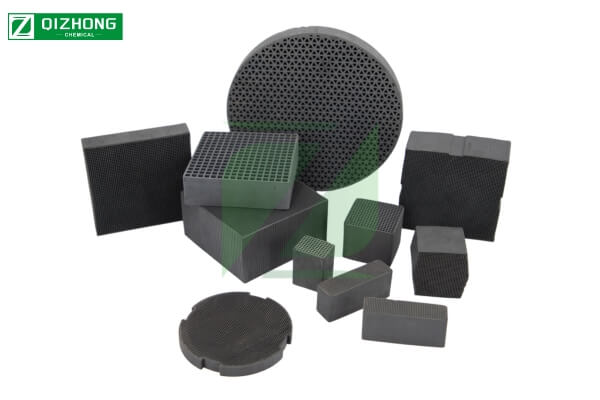

We are committed to meeting the diverse needs of our customers by providing many types of customized honeycomb activated carbon. Whether it is in terms of material, shape, impregnation type or performance index, we can customize the best solution for you.

Depending on your specific application needs, we offer a wide range of materials for cellular activated carbon, including wood, coal and coconut shells.

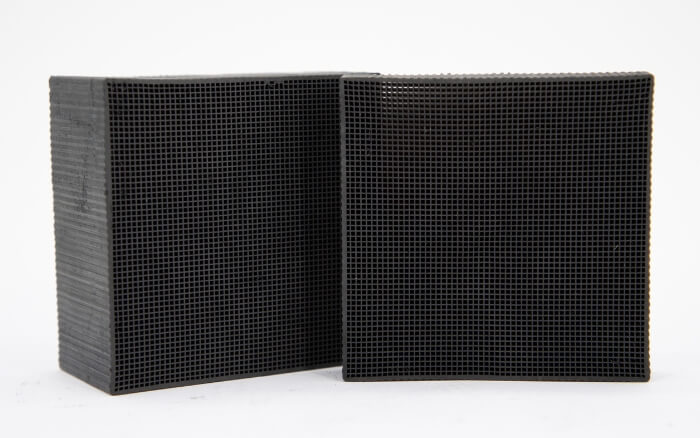

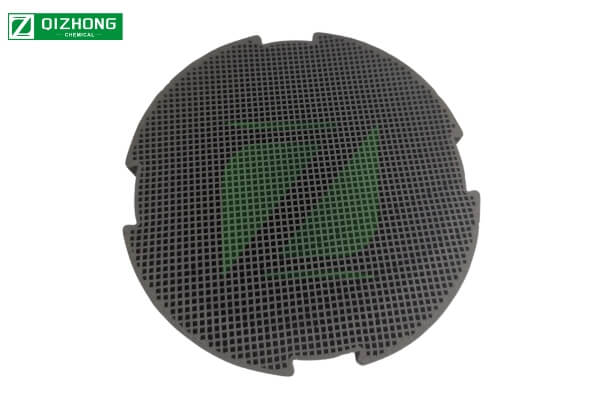

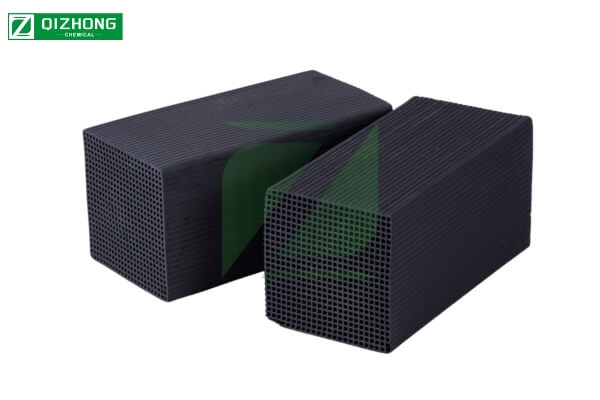

Common shapes include square, round and rectangular. We can customize the shape and size of our activated carbon to meet your requirements.

We offer a wide range of impregnation types, such as acidic, alkaline or other chemical impregnation, to meet specific purification and filtration needs.

We can adjust the performance index of honeycomb activated carbon, including specific surface area, pore size distribution, CTC, etc., to ensure the best purification effect and service life.

We offer a wide range of customization options, including material, impregnation, water resistance, shape, and more. Share your requirements with us and let our team provide the perfect solution for you.

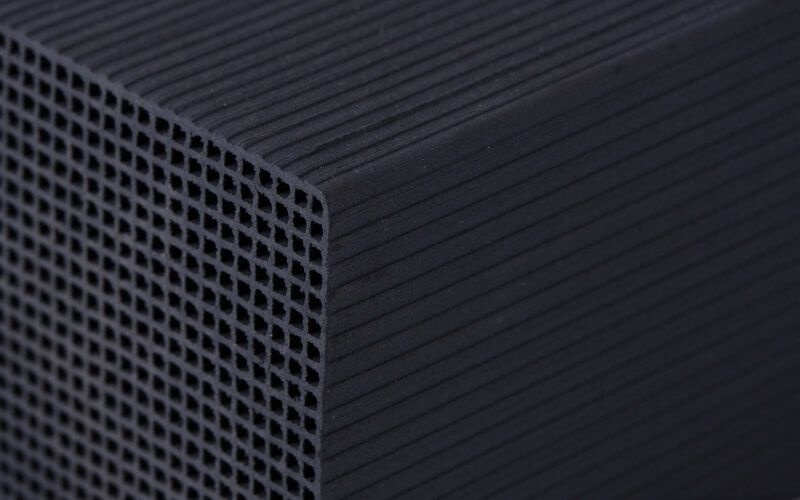

Honeycomb activated carbon is a new type of popular activated carbon, widely used in a variety of low concentration, low flow resistance purification system. It can effectively remove VOCs, odors, residual chlorine and organic matter.

Honeycomb activated carbon briquette is made from carbonized and activated organic materials with highly developed pore structure and large specific surface area. The main features of honeycomb activated carbon include:

We provide professional packaging services to ensure that the honeycomb activated carbon stays in the best condition during transportation and storage to meet the many needs of our customers.

Aliqua id fugiat nostrud irure ex duis ea quis id quis ad et. Sunt qui esse pariatur duis deserunt mollit dolore cillum minim tempor enim elit aute irure tempor cupidatat incididunt.

Professional manufacturer of both coal-based and coconut shell activated carbon with complete specifications

35000-ton annual capacity ensuring stable supply chain

Strict quality control system ensuring stable performance and international standard compliance

Serving 80+ countries with comprehensive international logistics solutions

Professional technical team providing application guidance and customized solutions

24-hour response time for inquiries, samples, and quotations

Competitive pricing through optimized production processes

Multiple international certifications including ISO, NSF, and HALAL

Find answers to common questions about our activated carbon products, ordering process, and technical support.

Honeycomb activated carbon is a specially shaped activated carbon, usually made into a honeycomb structure. It is made from carbonized and activated organic materials and has a highly developed pore structure and a large specific surface area, which enables it to efficiently adsorb pollutants such as volatile organic compounds (VOCs), odors, and chlorine from air and water.

It can be used directly or put into purification cabinet and adsorption bed, if the concentration of waste gas is high and the emission is large, two purification cabinets and adsorption beds can be used in rotation.

In the process of using, try to avoid high temperature, high temperature will reduce the adsorption amount, and the adsorption amount will decrease with the rise of temperature; at the same time, we should avoid high content of dust and oil mist, because the tar dust mist will block the micropores of activated carbon, increase the resistance, and reduce the adsorption effect, if the using environment contains a large amount of concentrated dust and tar, we should add the front stage of dust removal and filtration in order to achieve the best effect of use and the longest service life.

Contact us today to discuss your activated carbon needs. Our team is ready to provide expert support and solutions tailored to your requirements.