In today’s world, threats to the environment and health are everywhere, from pollution in the air and water sources to additives in food, posing challenges to our quality of life. In this context, activated carbon has become an important tool for us to combat these threats due to its unique adsorption properties.

This article aims to delve into the concept, types, working principles, and applications of activated carbon in various fields. By understanding the diversity and functionality of activated carbon, we can better utilize this resource to achieve a more efficient and environmentally friendly lifestyle.

#1 What is Activated Carbon?

Activated carbon is a porous carbon material that has undergone activation treatment on its surface, creating numerous micropores and mesopores that significantly increase its surface area. This allows activated carbon to possess a strong adsorption capacity, capable of capturing and trapping large amounts of organic and inorganic pollutants. In environmental protection, water purification, air purification, medicine, and chemical industries, activated carbon plays an irreplaceable role.

#2 Types of Activated Carbon

The diversity of activated carbon lies in the richness of its classification methods, mainly categorized by raw materials and forms. Based on different raw materials, activated carbon includes coconut shell activated carbon, coal activated carbon, and wood activated carbon, among others. While in terms of forms, activated carbon includes powdered activated carbon, granular activated carbon, cylindrical activated carbon, as well as special types of activated carbon like impregnated activated carbon and catalytic activated carbon.

These types of activated carbon are suitable for different fields and applications, understanding these classifications will help us to better select and utilize activated carbon to meet specific needs.

Classified by Raw Materials

Activated carbon is classified by raw materials, including coconut shell activated carbon, coal activated carbon, and wood activated carbon. Different types of activated carbon from different raw materials have specific advantages and application scopes in various fields.

Coconut Shell Activated Carbon

Coconut shell activated carbon is produced from coconut shells through a series of carbonization and activation processes. This process involves carbonizing the coconut shell and then steam activating it to form a highly porous structure, especially rich in micropores.

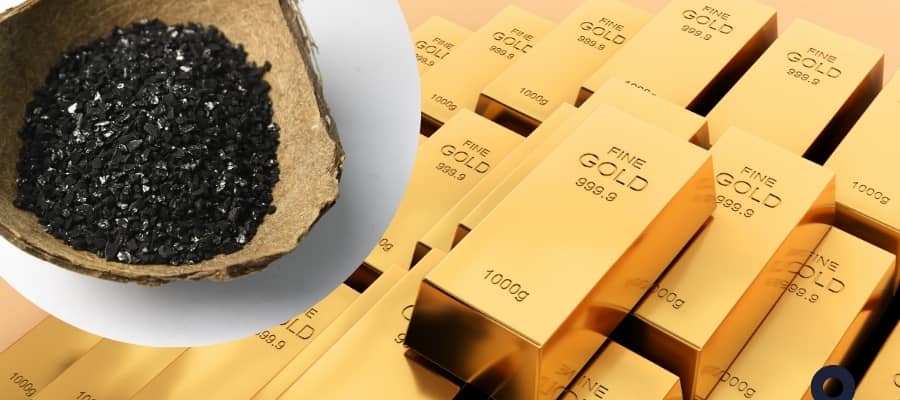

Due to its high surface area and excellent adsorption performance, coconut shell activated carbon is particularly suitable for water treatment, air purification, and is also an important adsorbent in gold recovery.

Coal Based Activated Carbon

Coal activated carbon is produced from coal through similar processes, but the activation process may vary, commonly using a rotary furnace for activation. Common forms include granular, powdered, cylindrical, and block cube forms.

Coal activated carbon, due to its higher mechanical strength, heat resistance, and cost-effectiveness, is often used in industrial gas treatment and large-scale water treatment facilities.

Wood Activated Carbon

Wood activated carbon is derived from various wood materials and can be obtained with specific pore structures through controlling the pyrolysis process and activation conditions.

Wood activated carbon is widely used in the pharmaceutical industry, food processing, and refining processes in the chemical industry to remove color, odor, and other impurities.

Classified by Shape and Form

Activated carbon can also be classified based on its shape and form, which influences its performance and efficiency in different applications.

Powdered Activated Carbon

Powdered activated carbon is a fine powder material with a high surface area, but due to its tendency to fly and difficulty in control, it is commonly used in batch treatment processes.

Granular Activated Carbon

Granular activated carbon consists of small granules and is easy to control and recover. They are commonly used in fluidized bed reactors and fixed bed filters to provide efficient liquid and gas treatment.

Extruded Activated Carbon

Extruded activated carbon is molded into cylindrical shapes, with lower dust generation and good flowability, suitable for continuous flow systems.

Activated Carbon Felts and Other Forms

Activated carbon felts are compressed carbon fiber materials into felt-like structures, along with other special shapes of activated carbon, such as honeycomb or plate-like forms, which can be customized according to specific filtration needs.

Special Types of Activated Carbon

Special types of activated carbon refer to activated carbon products that have undergone special treatments or have specific additives to give them unique functions.

Impregnated activated carbon

Impregnated activated carbon enhances its adsorption capacity for specific pollutants by adding specific chemical substances like silver, iodine, KI, KOH, etc. The advantage of impregnated activated carbon is its strong targeting ability to effectively remove target pollutants.

Catalytic activated carbon

Catalytic activated carbon not only has adsorption capability but also promotes specific chemical reactions. The surface of this activated carbon is modified to provide catalytic active sites, accelerating the rate of chemical reactions.

Catalytic activated carbon plays a crucial role in environmental remediation and industrial processes, particularly in exhaust gas treatment and conversion of harmful gases. It can convert harmful gases into harmless or easily treatable substances, reducing environmental pollution.

???? By utilizing these special types of activated carbon, we can more effectively address environmental and health challenges, achieving a cleaner and healthier living environment.

The above is a detailed introduction to the types of activated carbon. Next, the article will continue to explore the specific applications of activated carbon in various fields and how to optimize these applications by selecting the appropriate type of activated carbon.

#3 Applications of Activated Carbon

Activated carbon, as a porous adsorbent material, has a wide range of applications in various fields. From water treatment and air purification to food processing, healthcare, industrial production, waste treatment, and mining, activated carbon plays a crucial role. With its outstanding adsorption performance and diverse application areas, activated carbon serves an irreplaceable function in modern society.

Water Treatment

Water treatment is the most common application of activated carbon. With its excellent adsorption capabilities, it can remove suspended particles, organic pollutants, chlorine, odors, residual chlorine, heavy metals, and various other contaminants from water. This ensures the provision of clean, safe drinking water and industrial water, preventing industrial wastewater from polluting the environment. Activated carbon plays a key role in various water treatment processes such as municipal water treatment, process water purification, drinking water purification, and industrial wastewater treatment.

Air Purification

Activated carbon is widely used in gas purification. It can effectively remove harmful substances from indoor air, such as formaldehyde, benzene, and volatile organic compounds, improving indoor air quality and protecting people’s health. Additionally, activated carbon also plays an important role in automobile exhaust treatment systems, helping reduce emissions of harmful gases such as carbon monoxide and nitrogen oxides, thus reducing vehicle pollution to the environment.

Food Processing

In the food processing industry, activated carbon is used to enhance food quality and safety. It can remove colorants, odors, and impurities from food and beverages, ensuring pure taste and color, and improving product quality and safety. From sugars to wines, fruit juices, edible oils, and glycerol, activated carbon plays a crucial role, providing technical support and assurance for the food processing industry. Common types of activated carbon used include food-grade granular activated carbon and powdered activated carbon.

Pharmaceuticals

Activated carbon is mainly used for drug purification and pharmaceutical intermediate production. In drug manufacturing, activated carbon is used to remove impurities and catalyst residues from drugs, ensuring the safety and purity of pharmaceuticals.

Industrial Applications

In the industrial sector, activated carbon plays a crucial role, including but not limited to solvent recovery, impurity removal in refining, decolorization of waste engine oil, gas purification, and industrial wastewater treatment. These applications demonstrate the importance of activated carbon in the industrial sector, helping to improve production efficiency, product quality, and environmental protection levels.

Agricultural Applications

Activated carbon is used in agriculture to purify irrigation water, remove pesticide and fertilizer residues, protect crops and soil, and provide clean water sources in aquaculture to ensure the ecological health of aquatic animals.

Mining Industry

Activated carbon is used to recover gold from ore, mainly using granular activated carbon derived from coconut shells.

In addition to gold, activated carbon is also used to extract other precious metals such as platinum, silver, nickel, making it an indispensable material in modern mining industry.

#4 Working Principle of Activated Carbon

The reason activated carbon can play a significant role in various fields is attributed to its unique working principle. This section will delve into the adsorption process, pore structure, and activation process of activated carbon to understand how its powerful adsorption capacity is formed.

Adsorption Process

The adsorption capability of activated carbon mainly relies on two mechanisms: physical adsorption and chemical adsorption.

Physical Adsorption

- Physical adsorption refers to molecules being adsorbed onto the surface of activated carbon through weak van der Waals forces, which is a reversible process.

Chemical Adsorption

- Chemical adsorption involves the formation of chemical bonds between the surface of activated carbon and the adsorbate, which is usually stronger than physical adsorption but may be irreversible.

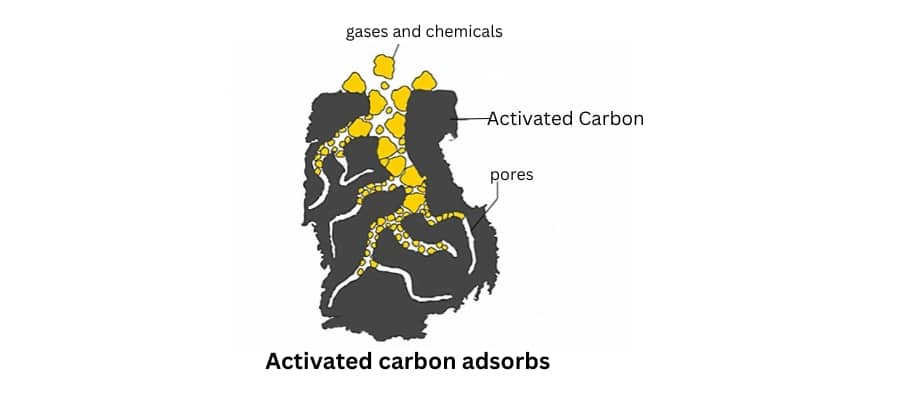

Pore Structure of Activated Carbon

The pore structure of activated carbon mainly includes micropores, mesopores, and macropores. The synergistic action of these pore structures gives activated carbon excellent adsorption performance, allowing it to efficiently remove harmful substances from liquids and gases.

Pore Structure of Activated Carbon

- Micropores: Pores with diameters less than 2 nanometers.

- Mesopores: Pores with diameters between 2-50 nanometers.

- Macropores: Pores with diameters larger than 50 nanometers.

Impact of Surface Area on Adsorption Capacity:

The adsorption capacity of activated carbon is directly proportional to its surface area. Through the activation process, the surface area of activated carbon can be significantly increased, thereby enhancing its adsorption efficiency.

Activation Process of Activated Carbon

The production process of activated carbon includes an activation step to open up its pore structure.

Thermal Activation

Thermal activation involves high-temperature treatment of raw materials to remove non-carbon components and form pores. Generally, activated carbons made from coal, coconut shells use high-temperature physical activation for production.

Chemical Activation

Chemical activation involves the use of chemical substances (such as acids or alkalis) to remove certain components and promote pore formation. Chemical activation is often used in the production of wood-based powdered activated carbon.

Conclusion

Activated carbon, as a porous adsorbent material, plays a significant role in various applications in today’s society.

With environmental pollution and health issues becoming increasingly severe, activated carbon, as an important environmental protection material and tool, will continue to play a crucial role. By understanding and utilizing the characteristics of activated carbon, we can collectively work towards achieving sustainable development and environmental protection goals.