Mercury is a major industrial pollutant that originates from oil extraction and coal power generation and poses serious health and environmental hazards.

Activated carbon is a commonly used method for mercury removal and is favored for its high capacity, flexibility and cost-effectiveness.

This paper will discuss the adsorption process and provide guidance on how to select the appropriate activated carbon to effectively treat mercury pollution.

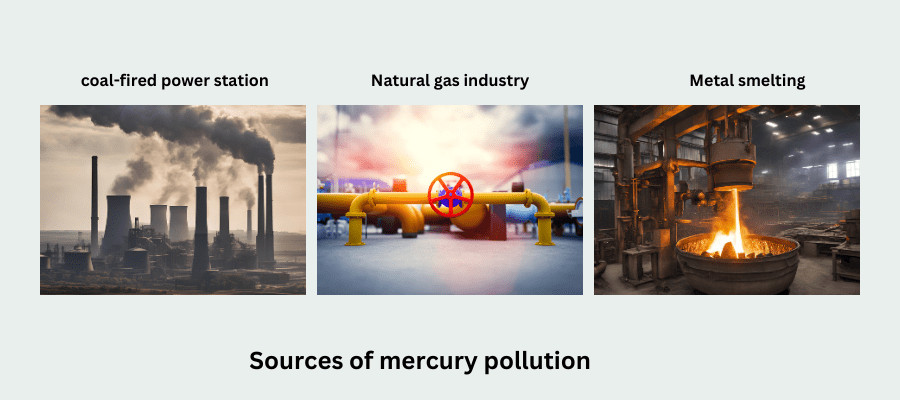

Sources and hazards of mercury pollution

Mercury pollution mainly comes from coal-fired power plants, the natural gas industry, industrial processes such as metal smelting, and the production and use of mercury-containing products. Mercury and its compounds can enter the environment through atmospheric deposition, wastewater discharge, and other pathways, and are enriched through the food chain, ultimately jeopardizing human health.

Increased public awareness of mercury has led to the development of various products utilizing activated carbon. Currently, activated carbon has been recognized as an effective technology for the control of mercury emissions from flue gas. Due to the high degree of microporosity and large surface area of activated carbon, mercury in the flue gas is adsorbed by the activated carbon, thus preventing its emission.

Forms of mercury in flue gas and adsorption on activated carbon

During industrial production, flue gas may contain three forms of mercury: monomeric mercury, oxidized mercury, and particulate mercury. Monomers are chemically stable and difficult to remove; oxidized mercury is soluble in water and can be removed by scrubbing towers; and particulate mercury is easily captured by dust removal and desulfurization equipment.

Activated carbon is a porous carbon material, and the tiny pores within it provide a large amount of adsorption space. When flue gas containing mercury passes through the activated carbon layer, large particles of mercury may be intercepted by the pores of the activated carbon layer and then adsorbed by the pores of the activated carbon, which can maximize its adsorption effect.

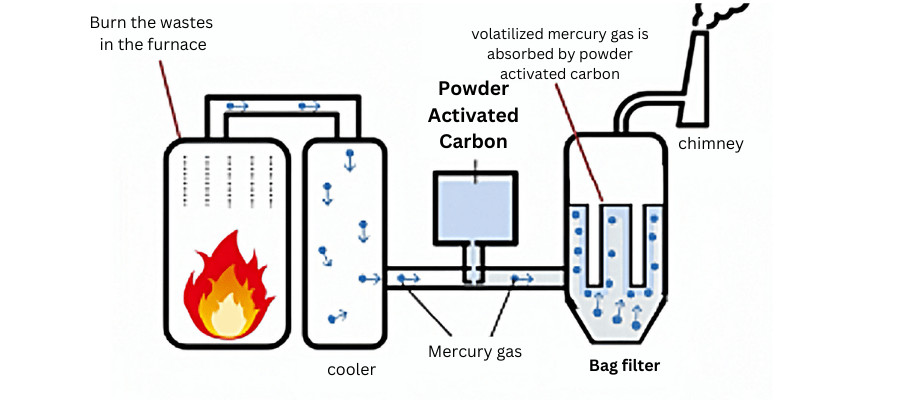

Mercury removal from incineration flue gas

The flue gas generated by the combustion of iron and steel plants, electric power plants and cement plants during the production process contains a variety of pollutants, including sulfur oxides, nitrogen oxides, heavy metals such as mercury, lead, cadmium, and fine particulate matter. These pollutants not only have a serious impact on air quality, but also cause serious harm to human health, even lead to chronic diseases and cancer, as well as environmental pollution and ecological damage.

Activated carbon plays an important role in the field of mercury removal from incineration flue gases due to its excellent adsorption properties. By modification, e.g. sulfur or halogen impregnation, to increase its mercury adsorption capacity treatment and optimization of the operating conditions, activated carbon can significantly increase the efficiency of mercury removal from flue gases and is a cost-effective and environmentally friendly solution for mercury removal.

In order to remove mercury substances from incineration flue gas, the commonly used activated carbon on the market is coal-based powdered activated carbon.

Coal-based powdered carbon is prepared through a carbonization and activation process and is an efficient flue gas purification material. It is widely used in coal-fired power plants and waste incineration plants to remove mercury vapors, heavy metals and persistent organic pollutants from flue gases to ensure that the emission gases meet the requirements of environmental protection and to protect the environment and human health.

The powdered activated carbon provided by Qizhong Company stands out from the crowd of flue gas purification materials due to its excellent product characteristics. It has the following distinctive features:

- Large number of high-energy adsorption pores

- Good transport pore structure

- Excellent fluidity and very low volatile matter content.

- High adsorption capacity for a wide range of pollutants

| Description | Coal Powder Activated Carbon |

| Mesh Size | 200/325 mesh |

| Iodine (mg/g) | 800-1050 |

| Moisture (%) Maximum | 5(max) |

| Ash≤(%) | 10 |

| Bulk density | ≤450g/l |

Natural Gas Mercury Removal

In natural gas and oil refineries, mercury can cause corrosion of equipment, affecting normal operation and service life, and handling mercury helps maintain the integrity and safety of industrial facilities. In addition, removing mercury present in the refining process improves the quality and safety of the final product to meet market demands. Therefore, the development of effective natural gas mercury removal technologies is critical to maintaining the integrity and safety of industrial facilities.

Natural gas mercury removal technologies include the following two main approaches:

- Fixed-bed adsorption for mercury removal: mercury removal is achieved by filling the mercury removal tower with a mercury removal adsorbent, commonly used adsorbents include Sulfur-carrying activated carbon, metal sulfide and silver-carrying molecular sieves, so that the mercury in the natural gas reacts with the adsorbent to form mercury compounds or is adsorbed. Mercury removal rate of 90% to 95% or more can be achieved, which is a method with simple process flow and low investment cost.

- Natural gas cooling for mercury removal: Using the property that mercury is in liquid state at room temperature and pressure, mercury is separated in liquid form by cooling natural gas to below zero degree to realize mercury removal. This method has a mercury removal rate of over 90%, is a simple process and the removed mercury can be recycled, contributing to cleaner production.

The use of these advanced mercury removal technologies effectively removes mercury from natural gas and refinery emissions while minimizing potential hazards to equipment and the environment, enhancing product value, and protecting society and the environment.

The activated carbon offered by Qizhong for the removal of mercury from natural gas is sulfur-impregnated granular activated carbon.

Sulfur impregnated granular activated carbon is a highly efficient adsorbent that has undergone a special chemical treatment in which sulfur or sulfur-containing compounds are impregnated into the pore structure of the activated carbon during the preparation process. Used in the oil and gas industry, it is suitable for trapping and immobilizing mercury vapors emitted during oil and gas processing and preventing them from entering the atmosphere, with enhanced chemical adsorption of mercury through the sulfur impregnation process.

| Description | Sulfur impregnated granular activated carbon |

| Mesh Size | 4*10 mesh |

| Iodine (mg/g) | 800-1000 |

| Moisture (%) Maximum | 10 |

| Hardness (%) Minimum | 90 |

In addition, impregnated columnar activated carbon is a highly efficient material for mercury removal and is widely used in the treatment of natural gas, air, carbon monoxide (CO), and other industrial exhaust gases containing elemental mercury. Especially in LNG and LPG plants, the use of this activated carbon effectively removes mercury from the feed gas, protecting equipment such as aluminum heat exchangers from corrosion and extending their service life.

The impregnated columnar activated carbon offered by Qizhong Company is highly respected in the field of industrial flue gas purification for its unique advantages. It possesses the following distinctive features:

- High mercury capacity

- Low pressure drop

- Low dust

| Description | Impregnated Column Activated Carbon |

| Mesh Size | 4mm |

| CCL4/CTC (%) Minimum | 60 |

| Moisture (%) Maximum | 5 |

| Hardness (%) Minimum | 95 |

| Sulfur impregnated content | ≥10% |

| Bulk density | ≥450g/l |

The special activated carbon for mercury removal developed by our company has undergone in-depth systematic optimization in the selection of raw materials, activation process, surface modification, etc., which ensures that the product can still maintain excellent mercury removal performance under different environments.

Conclusion

Choosing a professional and reliable activated carbon supplier is crucial for mercury pollution treatment. Our activated carbon products are subject to strict quality control to ensure the highest adsorption efficiency and safety. We provide not only products, but also comprehensive technical support and customized solutions.

For further information or to discuss how our activated carbon products can improve your mercury treatment, please contact us .