Introduction

When it comes to choosing the right activated carbon for your specific purification needs, understanding the various types available is crucial for optimal performance. At Qizhong Carbon, with over 20 years of experience in activated carbon innovation, we’ve seen firsthand how selecting the appropriate activated carbon format can make a significant difference in project outcomes.

Activated carbon remains one of the most versatile and effective adsorbent materials in the world, with applications ranging from water purification to air filtration, pharmaceutical processing, and industrial gas treatment. However, not all activated carbons are created equal. The physical form, raw material source, and specific activation process all contribute to the overall performance characteristics that determine effectiveness in different applications.

In this comprehensive guide, we’ll explore the major types of activated carbon available on the market and help you understand which variety is best suited for your specific purification challenges.

Types of Activated Carbon by Physical Form

Granular Activated Carbon (GAC)

Granular activated carbon consists of irregularly shaped particles typically ranging from 0.2 to 5 mm in size. GAC offers an excellent balance between surface area accessibility and pressure drop characteristics, making it ideal for continuous flow systems.

Key characteristics of GAC include:

- Versatile application: Works effectively in both liquid and gas phase treatments

- Mechanical strength: Withstands backwashing and handling with minimal breakage

- Regeneration capability: Can be thermally or chemically regenerated multiple times

- Cost-effectiveness: Offers a good balance of initial cost and service life

GAC is particularly well-suited for drinking water treatment, groundwater remediation, and aquarium filtration where a fixed bed contactor is used. Most installations use specific mesh sizes (such as 8×30, 12×40, or 20×50) selected based on the specific application requirements and flow rate considerations.

Powdered Activated Carbon (PAC)

Powdered activated carbon features much finer particles than GAC, typically less than 0.1 mm in size (passing through a 100-mesh screen). This smaller particle size creates a larger external surface area, resulting in faster adsorption kinetics.

PAC advantages include:

- Rapid adsorption: Much faster kinetics compared to larger particle forms

- Dosing flexibility: Can be added in varying amounts based on contaminant levels

- Lower initial investment: Often requires less specialized equipment for application

- Higher utilization rate: Smaller particles result in more complete carbon usage

PAC is commonly used for emergency response situations, such as taste and odor events in municipal water supplies, wastewater treatment, and batch process industrial applications where carbon doesn’t need to be recovered after use.

Extruded Activated Carbon (EAC)

Extruded activated carbon, also known as pelletized carbon, is formed by combining powdered activated carbon with a binder and extruding the mixture into cylindrical pellets with diameters ranging from 0.8 to 5 mm.

Key benefits of EAC include:

- Excellent flow dynamics: Creates predictable pressure drop in gas-phase applications

- Low dust content: Minimizes downstream contamination issues

- High mechanical strength: Maintains its structure even under pressure

- Uniform bed packing: Provides consistent contact time throughout the bed

EAC is primarily used in gas phase applications such as VOC removal, air purification systems, and industrial gas treatment where pressure drop considerations are critical to system performance.

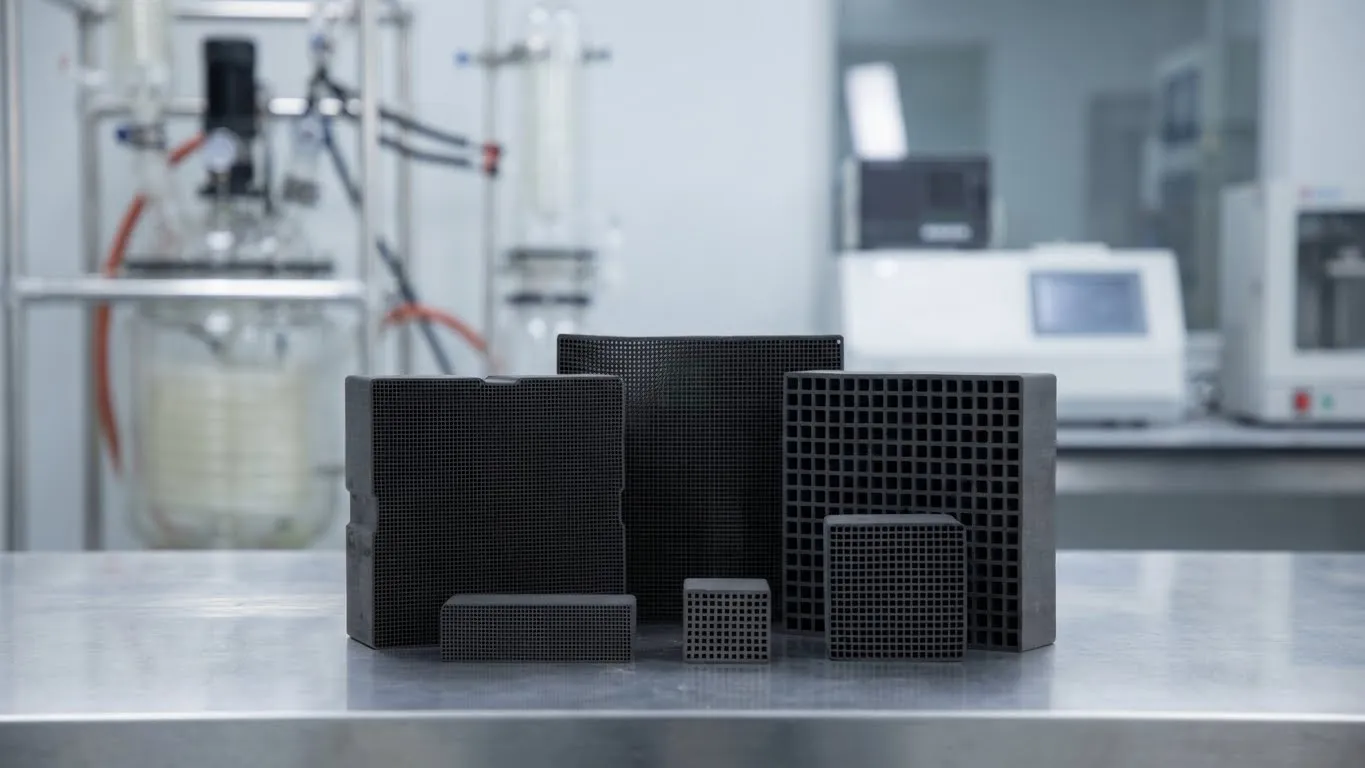

Honeycomb Activated Carbon

For applications where minimal pressure drop is essential, honeycomb activated carbon offers a specialized geometric structure. This format features parallel channels that allow for efficient gas flow while maintaining excellent contact with the adsorption surface.

Honeycomb activated carbon provides:

- Extremely low pressure drop: Reduces energy requirements for gas treatment

- High geometric surface area: Maximizes contact efficiency

- Structured flow path: Eliminates channeling issues common in granular beds

- Mechanical durability: Withstands vibration and mechanical stress

This specialized form is particularly valuable in automotive emissions control, HVAC systems, and other applications where energy efficiency is a primary consideration.

Types of Activated Carbon by Raw Material

The base material used to create activated carbon significantly influences its performance characteristics, making material selection an important factor in choosing the right product for specific applications.

Coal-Based Activated Carbon

Coal-based activated carbon offers a well-balanced pore structure distribution, making it suitable for a wide range of applications.

Key properties of coal-based carbon include:

- Balanced porosity: Contains a good mix of micro, meso, and macropores

- High hardness: Excellent mechanical strength and abrasion resistance

- Versatile adsorption profile: Effective for both organic and inorganic contaminants

- Cost-effective performance: Often provides the best value for general applications

Coal-based activated carbon is commonly used in municipal water treatment, wastewater processing, and industrial applications where a broad spectrum of contaminants needs to be addressed simultaneously.

Coconut Shell Activated Carbon

Derived from coconut shells, this type of activated carbon is characterized by its predominately microporous structure, making it ideal for removing small molecule contaminants.

Advantages of coconut shell carbon include:

- Abundant microporosity: Superior for adsorbing small molecules and trace contaminants

- High hardness: Excellent durability for repeated use cycles

- Clean profile: Minimal ash content and extractable impurities

- Renewable source: Environmentally sustainable raw material

Coconut shell activated carbon performs exceptionally well in specialized applications such as air purification, volatile organic compound (VOC) removal, gold recovery, and point-of-use water treatment systems where removal of chlorine, pesticides, and other small organic molecules is required.

Wood-Based Activated Carbon

Wood-based activated carbon has a unique pore structure dominated by mesopores and macropores, making it particularly effective for adsorbing larger molecular weight compounds.

Wood-based carbon features:

- Predominant mesopores: Excellent for larger organic molecules

- Superior decolorization: Effectively removes color-causing compounds

- Lower density: Higher volume per weight compared to other raw materials

- Renewable resource: Environmentally responsible sourcing

This type is particularly effective in applications such as food processing, pharmaceutical production, and chemical purification where color removal and large molecule adsorption are primary concerns.

Specialized Activated Carbon Types

Impregnated Activated Carbon

For specialized applications requiring targeted removal of specific compounds, impregnated activated carbons offer enhanced capabilities beyond standard physical adsorption.

Common impregnated activated carbon types include:

- Sulfur-impregnated carbon: Effective for mercury and heavy metal removal

- Silver-impregnated carbon: Offers antimicrobial properties for water disinfection

- Potassium iodide (KI) impregnated carbon: Used for radioactive iodine removal

- Caustic impregnated carbon: Specialized for acid gas removal

These specialized carbons combine the physical adsorption capabilities of activated carbon with chemical reactions provided by the impregnants, creating targeted solutions for challenging contaminants that cannot be effectively removed by standard activated carbon.

Catalytic Activated Carbon

Catalytic activated carbons are specially treated to enhance their ability to promote chemical reactions beyond simple adsorption. These carbons can facilitate oxidation, reduction, or decomposition of certain contaminants.

Applications for catalytic activated carbon include:

- Chloramine removal: Catalytically breaks down chloramines in water treatment

- Hydrogen sulfide oxidation: Converts H₂S to elemental sulfur

- VOC destruction: Enhances breakdown of volatile organic compounds

- Ozone decomposition: Converts ozone to oxygen in water treatment

These specialized carbons find use in advanced water treatment systems, industrial gas purification, and environmental remediation where contaminant transformation is as important as removal.

Selecting the Right Activated Carbon

Choosing the appropriate activated carbon involves consideration of several factors:

- Contaminant profile: What specific compounds need to be removed?

- Particle size requirements: What are the system flow requirements and pressure drop constraints?

- Adsorption kinetics: How quickly must the contaminant be removed?

- Regeneration needs: Will the carbon need to be regenerated, and by what method?

- System constraints: What are the physical limitations of the treatment system?

At Qizhong Carbon, our technical team works closely with clients to identify the optimal activated carbon solution for their specific requirements. Our comprehensive range includes granular, powdered, extruded, and impregnated carbons manufactured from various raw materials to meet diverse application needs.

Conclusion

Understanding the different types of activated carbon is essential for designing effective purification systems. From granular to powdered, coal-based to coconut shell, each variety offers distinct advantages for specific applications. By matching the right activated carbon type to your particular contaminant challenges and system requirements, you can achieve optimal performance and cost-effectiveness.

For personalized assistance selecting the ideal activated carbon for your application, contact our technical experts at Qizhong Carbon. With over 20 years of experience in activated carbon manufacturing and application, we can help you navigate the complexities of carbon selection to find the perfect solution for your purification needs.

Contact us today at info@qizhongcarbon.com or call +86-19137612950 to discuss your specific activated carbon requirements.